What are the Product Standards for Fan Capacitors?

I. Introduction

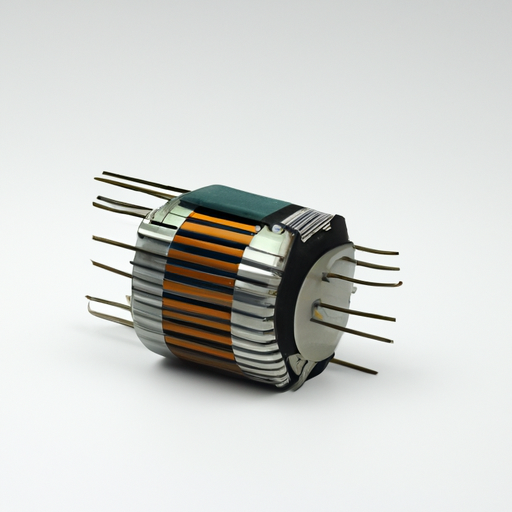

Fan capacitors are essential components in various electrical systems, particularly in fans and motors. They play a crucial role in ensuring that these devices operate efficiently and reliably. As with any electrical component, product standards are vital for fan capacitors, ensuring safety, performance, and compatibility across different applications. This article aims to explore the significance of product standards for fan capacitors, the key standards that govern their manufacturing and testing, and the future trends that may influence these standards.

II. Understanding Fan Capacitors

A. Function of Fan Capacitors in Electrical Systems

Fan capacitors serve two primary functions in electrical systems: starting and running motors.

1. **Role in Starting and Running Motors**: Start capacitors provide the necessary torque to initiate the motor's operation, while run capacitors maintain the motor's efficiency during operation. Without these capacitors, motors would struggle to start or run smoothly, leading to increased wear and potential failure.

2. **Impact on Efficiency and Performance**: The efficiency of a fan or motor is significantly influenced by the quality and type of capacitor used. Properly rated capacitors can enhance performance, reduce energy consumption, and extend the lifespan of the motor.

B. Types of Fan Capacitors

There are three main types of fan capacitors:

1. **Start Capacitors**: These capacitors are designed to provide a short burst of energy to start the motor. They are typically used in applications where high starting torque is required.

2. **Run Capacitors**: Unlike start capacitors, run capacitors remain in the circuit during the motor's operation, helping to improve efficiency and performance.

3. **Dual Capacitors**: These capacitors combine the functions of both start and run capacitors in a single unit, making them suitable for specific applications where space and efficiency are concerns.

III. Importance of Product Standards

A. Ensuring Safety and Reliability

Product standards are crucial for ensuring the safety and reliability of fan capacitors. They establish guidelines for manufacturing processes, materials, and testing procedures, helping to minimize the risk of failures that could lead to hazardous situations.

B. Promoting Compatibility and Interoperability

Standards facilitate compatibility between different manufacturers' products, ensuring that components can work together seamlessly. This interoperability is essential in applications where multiple components are used, such as in HVAC systems.

C. Enhancing Performance and Efficiency

By adhering to established standards, manufacturers can produce capacitors that meet specific performance criteria, leading to improved efficiency and reduced energy consumption in electrical systems.

D. Regulatory Compliance and Market Access

Compliance with product standards is often a legal requirement for selling electrical components in various markets. Meeting these standards can enhance a manufacturer's reputation and open doors to new markets.

IV. Key Product Standards for Fan Capacitors

A. International Electrotechnical Commission (IEC) Standards

1. **Overview of IEC Standards Relevant to Capacitors**: The IEC develops international standards for electrical and electronic devices, including capacitors. These standards cover safety, performance, and testing requirements.

2. **Specific IEC Standards for Fan Capacitors**: IEC 60252-1 is a key standard that outlines the general requirements for capacitors used in AC motors, including fan capacitors. It specifies testing methods, performance criteria, and safety requirements.

B. Underwriters Laboratories (UL) Standards

1. **Importance of UL Certification**: UL is a globally recognized safety certification organization. Products that meet UL standards are tested for safety and performance, providing assurance to consumers and manufacturers.

2. **Relevant UL Standards for Fan Capacitors**: UL 810 is a standard that applies to capacitors for use in AC applications, including fan capacitors. It covers safety requirements and testing methods to ensure reliability.

C. American National Standards Institute (ANSI) Standards

1. **Overview of ANSI Standards**: ANSI oversees the development of consensus standards for various industries in the United States, including electrical components.

2. **Specific ANSI Standards Applicable to Fan Capacitors**: ANSI C37.90 outlines the performance requirements for capacitors used in electrical equipment, ensuring they meet safety and operational standards.

D. Other Relevant Standards

1. **National Electrical Manufacturers Association (NEMA)**: NEMA develops standards for electrical equipment, including guidelines for the performance and testing of capacitors.

2. **European Committee for Electrotechnical Standardization (CENELEC)**: CENELEC establishes standards for electrical components in Europe, ensuring safety and performance across the region.

V. Testing and Certification Processes

A. Overview of Testing Procedures for Fan Capacitors

1. **Electrical Testing**: This involves measuring the electrical characteristics of the capacitor, such as capacitance, voltage rating, and leakage current, to ensure they meet specified standards.

2. **Mechanical Testing**: Mechanical tests assess the physical integrity of the capacitor, including its ability to withstand vibrations, shocks, and temperature variations.

3. **Environmental Testing**: Environmental tests evaluate the capacitor's performance under various conditions, such as humidity, temperature extremes, and exposure to corrosive substances.

B. Certification Bodies and Their Roles

1. **Importance of Third-Party Testing**: Third-party testing by recognized certification bodies ensures that products meet established standards, providing an additional layer of assurance for manufacturers and consumers.

2. **Examples of Recognized Certification Bodies**: In addition to UL, other notable certification bodies include Intertek, TUV Rheinland, and SGS, all of which conduct rigorous testing and certification processes.

VI. Compliance and Quality Assurance

A. Importance of Compliance with Product Standards

Compliance with product standards is essential for ensuring the safety and reliability of fan capacitors. It helps manufacturers avoid legal issues and enhances their reputation in the market.

B. Quality Assurance Practices in Manufacturing

1. **Quality Control Measures**: Implementing strict quality control measures during the manufacturing process helps ensure that capacitors meet performance and safety standards.

2. **Continuous Improvement Processes**: Manufacturers should adopt continuous improvement practices to enhance product quality and adapt to changing standards and technologies.

C. Consequences of Non-Compliance

Failure to comply with product standards can result in product recalls, legal liabilities, and damage to a manufacturer's reputation. It can also pose safety risks to consumers.

VII. Future Trends in Fan Capacitor Standards

A. Emerging Technologies and Their Impact on Standards

As technology advances, new materials and manufacturing processes are being developed for fan capacitors. These innovations may lead to updated standards that reflect the capabilities of modern components.

B. Sustainability and Environmental Considerations

There is a growing emphasis on sustainability in manufacturing practices. Future standards may incorporate environmental considerations, promoting the use of eco-friendly materials and energy-efficient designs.

C. Anticipated Changes in Regulatory Frameworks

Regulatory frameworks governing electrical components are continually evolving. Manufacturers must stay informed about potential changes to standards and regulations to ensure ongoing compliance.

VIII. Conclusion

In conclusion, product standards for fan capacitors are essential for ensuring safety, performance, and reliability in electrical systems. These standards not only protect consumers but also promote compatibility and efficiency across various applications. As technology continues to evolve, manufacturers and consumers alike must prioritize compliance with these standards to foster a safe and efficient electrical environment. By understanding and adhering to product standards, we can ensure that fan capacitors contribute positively to the performance of electrical systems.

IX. References

- International Electrotechnical Commission (IEC)

- Underwriters Laboratories (UL)

- American National Standards Institute (ANSI)

- National Electrical Manufacturers Association (NEMA)

- European Committee for Electrotechnical Standardization (CENELEC)

- Various academic and industry publications on fan capacitors and standards

This comprehensive overview of product standards for fan capacitors highlights their critical role in the electrical industry, emphasizing the need for adherence to established guidelines to ensure safety and performance.