What is the Price of Popular Capacitor Factory Models in Stock?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from filtering signals in audio equipment to stabilizing voltage in power supplies. The capacitor manufacturing industry has evolved significantly, driven by advancements in technology and increasing demand across multiple sectors, including consumer electronics, automotive, and renewable energy. This article aims to provide insights into the pricing of popular capacitor factory models, helping readers understand the factors that influence these prices and where to find them.

II. Understanding Capacitor Types

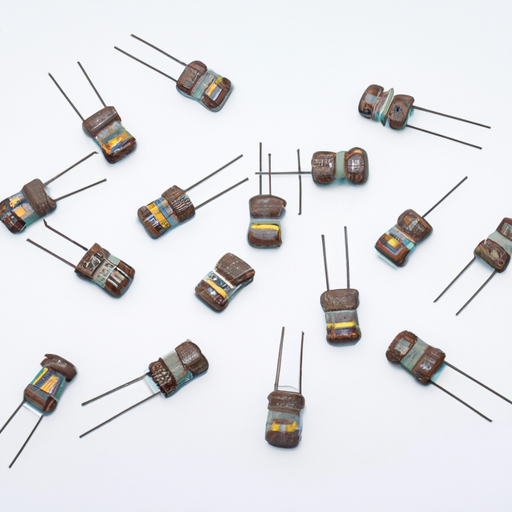

Capacitors come in various types, each suited for specific applications. Here’s a brief overview of the most common types:

A. Overview of Different Types of Capacitors

1. **Ceramic Capacitors**: These are widely used due to their small size and reliability. They are ideal for high-frequency applications and are often found in RF circuits and decoupling applications.

2. **Electrolytic Capacitors**: Known for their high capacitance values, electrolytic capacitors are typically used in power supply circuits. They are polarized, meaning they must be connected in the correct direction.

3. **Film Capacitors**: These capacitors are known for their stability and low loss characteristics. They are commonly used in audio applications and power electronics.

4. **Tantalum Capacitors**: Tantalum capacitors offer high capacitance in a small package and are often used in portable electronics. They are also polarized and can be more expensive than other types.

5. **Supercapacitors**: These are used for energy storage applications, providing high capacitance and rapid charge/discharge cycles. They are increasingly popular in renewable energy systems and electric vehicles.

B. Applications of Each Type in Various Industries

Each type of capacitor has unique properties that make it suitable for specific applications. For instance, ceramic capacitors are favored in high-frequency circuits, while electrolytic capacitors are essential in power supply applications. Understanding these applications helps in selecting the right capacitor for a project.

III. Factors Influencing Capacitor Prices

Several factors contribute to the pricing of capacitors, making it essential for buyers to understand these dynamics.

A. Material Costs

1. **Raw Materials Used in Capacitor Production**: The cost of raw materials, such as tantalum, aluminum, and ceramic substrates, significantly impacts capacitor prices. Fluctuations in the prices of these materials can lead to variations in the final product cost.

2. **Impact of Material Scarcity on Pricing**: Scarcity of certain materials, particularly tantalum, can drive prices up. This is especially relevant in times of geopolitical instability or supply chain disruptions.

B. Manufacturing Processes

1. **Complexity of Production Methods**: The manufacturing process for capacitors can vary in complexity. More intricate processes often lead to higher production costs, which are reflected in the retail price.

2. **Automation vs. Manual Labor**: Factories that utilize advanced automation may have lower labor costs, potentially leading to more competitive pricing. Conversely, manufacturers relying on manual labor may face higher costs.

C. Market Demand and Supply Dynamics

1. **Seasonal Fluctuations**: Demand for capacitors can fluctuate seasonally, particularly in industries like consumer electronics, where new product launches often occur at specific times of the year.

2. **Technological Advancements**: As technology evolves, new capacitor types and models may emerge, influencing the pricing of existing products. Manufacturers may adjust prices based on the introduction of more efficient or higher-performing capacitors.

D. Brand Reputation and Quality Assurance

1. **Established Brands vs. New Entrants**: Well-known brands often command higher prices due to their reputation for quality and reliability. New entrants may offer lower prices to gain market share, but this can come with risks regarding quality.

2. **Certifications and Standards Compliance**: Capacitors that meet specific industry standards or certifications may be priced higher due to the assurance of quality and reliability they provide.

IV. Popular Capacitor Factory Models

A. Overview of Leading Manufacturers

Several manufacturers dominate the capacitor market, each offering a range of popular models:

1. **Murata Manufacturing Co.**: Known for its high-quality ceramic capacitors, Murata offers models suitable for various applications, including RF and power supply circuits.

2. **Vishay Intertechnology**: Vishay produces a wide range of capacitors, including tantalum and film capacitors, known for their reliability and performance.

3. **KEMET Corporation**: KEMET is recognized for its extensive selection of electrolytic and film capacitors, catering to diverse industries.

4. **Nichicon Corporation**: Specializing in electrolytic capacitors, Nichicon is a trusted name in the electronics industry, particularly in power supply applications.

5. **Panasonic Corporation**: Panasonic offers a broad range of capacitors, including supercapacitors, known for their innovative designs and high performance.

B. Description of Popular Models from Each Manufacturer

1. **Murata GRM Series**: These ceramic capacitors are compact and suitable for high-frequency applications, with capacitance values ranging from picofarads to microfarads.

2. **Vishay 293D Series**: This tantalum capacitor series is known for its reliability and is commonly used in portable electronics.

3. **KEMET A700 Series**: These aluminum electrolytic capacitors are designed for high-performance applications, offering a wide capacitance range.

4. **Nichicon UHE Series**: This series of electrolytic capacitors is known for its long life and stability, making it ideal for power supply circuits.

5. **Panasonic EEC-F Series**: These supercapacitors are designed for energy storage applications, providing high capacitance and rapid charge/discharge capabilities.

V. Price Ranges for Popular Capacitor Models

A. Price Comparison of Different Types of Capacitors

1. **Ceramic Capacitors**: Prices typically range from $0.01 to $1.00, depending on capacitance and voltage ratings. For example, a standard 10µF ceramic capacitor may cost around $0.10.

2. **Electrolytic Capacitors**: These can range from $0.05 to $5.00, with larger capacitance values commanding higher prices. A 1000µF electrolytic capacitor might cost around $0.50.

3. **Film Capacitors**: Prices generally range from $0.10 to $3.00. A common 1µF film capacitor may be priced at approximately $0.20.

4. **Tantalum Capacitors**: These are usually more expensive, ranging from $0.50 to $10.00. A 10µF tantalum capacitor could cost around $1.50.

5. **Supercapacitors**: Prices can vary widely, from $1.00 to $50.00, depending on capacitance and voltage. A 100F supercapacitor might be priced at around $10.00.

B. Factors Affecting Price Variations Within Each Type

Price variations within each type of capacitor can be influenced by factors such as brand reputation, manufacturing processes, and market demand. For instance, a high-end ceramic capacitor from a reputable brand may cost significantly more than a generic version.

VI. Where to Buy Capacitors

A. Overview of Distribution Channels

1. **Online Retailers**: Websites like Digi-Key, Mouser, and Amazon offer a wide selection of capacitors, often with competitive pricing and convenient shipping options.

2. **Electronic Component Distributors**: Distributors like Newark and Allied Electronics provide access to a broad range of components, including capacitors, often with bulk purchasing options.

3. **Direct from Manufacturers**: Purchasing directly from manufacturers can sometimes yield better pricing, especially for bulk orders.

B. Tips for Purchasing Capacitors

1. **Evaluating Supplier Reliability**: Always check supplier reviews and ratings to ensure reliability and quality.

2. **Understanding Warranty and Return Policies**: Familiarize yourself with the warranty and return policies to avoid potential issues with defective products.

3. **Importance of Bulk Purchasing for Cost Savings**: Buying in bulk can lead to significant cost savings, especially for businesses that require large quantities of capacitors.

VII. Conclusion

Understanding capacitor pricing is essential for anyone involved in electronics, whether for personal projects or professional applications. The capacitor market is influenced by various factors, including material costs, manufacturing processes, and market dynamics. As technology continues to advance, staying informed about pricing trends and new developments in capacitor technology will be crucial for making informed purchasing decisions.

VIII. References

- Industry reports and market analysis documents

- Manufacturer websites for detailed product specifications

- Online retailers for current pricing and availability

By understanding the complexities of capacitor pricing and the factors that influence it, readers can make informed decisions when purchasing these essential electronic components.