Popular Models of Thermal Resistors

I. Introduction

Thermal resistors, also known as temperature sensors, are crucial components in various electronic and industrial applications. They measure temperature by correlating the resistance of a material to its temperature. Understanding thermal resistors is essential for engineers and designers who need to monitor and control temperature in systems ranging from consumer electronics to industrial machinery. This article will explore the different types of thermal resistors, popular models, their applications, and future trends in thermal resistor technology.

II. Understanding Thermal Resistance

A. Explanation of Thermal Resistance and Its Significance

Thermal resistance is a measure of a material's ability to resist the flow of heat. It is analogous to electrical resistance in circuits, where a higher resistance means less current flow. In thermal systems, a higher thermal resistance indicates that the material is less effective at conducting heat. This property is significant in applications where temperature control is critical, such as in HVAC systems, electronic devices, and automotive applications.

B. Factors Affecting Thermal Resistance

Several factors influence thermal resistance, including:

1. **Material Properties**: Different materials have varying thermal conductivities. Metals like copper and aluminum have low thermal resistance, while insulators like rubber and glass have high thermal resistance.

2. **Geometry and Dimensions**: The shape and size of the material also affect thermal resistance. Thicker materials generally have higher thermal resistance, while larger surface areas can enhance heat transfer.

3. **Environmental Conditions**: Temperature, pressure, and humidity can alter the thermal resistance of materials, impacting their performance in real-world applications.

III. Types of Thermal Resistors

A. Overview of Different Types of Thermal Resistors

Thermal resistors come in various types, each suited for specific applications:

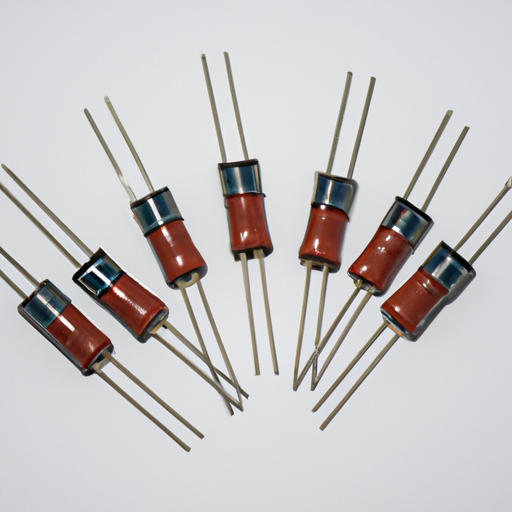

1. **Thermistors**: These are temperature-sensitive resistors that exhibit a significant change in resistance with temperature variations. They are widely used in temperature sensing and control applications.

2. **RTDs (Resistance Temperature Detectors)**: RTDs are highly accurate temperature sensors that use the principle of electrical resistance change with temperature. They are commonly used in industrial applications.

3. **Bimetallic Temperature Sensors**: These sensors consist of two different metals bonded together, which expand at different rates when heated. They are often used in thermostats and temperature switches.

4. **Infrared Thermal Sensors**: These sensors detect infrared radiation emitted by objects, allowing for non-contact temperature measurement. They are used in various applications, including medical devices and industrial monitoring.

IV. Popular Models of Thermal Resistors

A. Thermistors

1. NTC (Negative Temperature Coefficient) Thermistors

NTC thermistors decrease in resistance as temperature increases. They are widely used in temperature measurement and control applications due to their high sensitivity.

Characteristics and Applications: NTC thermistors are known for their fast response times and high accuracy. They are commonly used in temperature monitoring in HVAC systems, automotive applications, and consumer electronics.

Popular Models:

EPCOS B57891: This NTC thermistor is known for its high sensitivity and stability, making it suitable for various applications, including temperature measurement in appliances.

Vishay NTCLE100E3: This model offers excellent linearity and is widely used in medical devices and industrial applications.

2. PTC (Positive Temperature Coefficient) Thermistors

PTC thermistors increase in resistance as temperature rises. They are often used for overcurrent protection and self-regulating heating applications.

Characteristics and Applications: PTC thermistors are known for their ability to limit current flow in overcurrent situations. They are commonly used in power supplies, motor protection, and heating elements.

Popular Models:

EPCOS B57231: This PTC thermistor is designed for overcurrent protection and is widely used in consumer electronics.

Vishay PTC: This model is known for its reliability and is used in various applications, including automotive and industrial systems.

B. Resistance Temperature Detectors (RTDs)

RTDs are known for their accuracy and stability over a wide temperature range.

Characteristics and Applications: RTDs provide precise temperature measurements and are commonly used in industrial processes, HVAC systems, and laboratory settings.

Popular Models:

PT100: This is one of the most common RTD types, with a resistance of 100 ohms at 0°C. It is widely used in various applications due to its accuracy and reliability.

PT1000: Similar to the PT100, this RTD has a resistance of 1000 ohms at 0°C, offering higher sensitivity and is often used in applications requiring precise temperature control.

C. Bimetallic Temperature Sensors

Bimetallic temperature sensors are simple yet effective devices that use the expansion of two different metals to measure temperature.

Characteristics and Applications: These sensors are robust and can operate in harsh environments. They are commonly used in thermostats, temperature switches, and industrial applications.

Popular Models:

Honeywell Bimetallic Thermostats: Known for their reliability and durability, these thermostats are widely used in HVAC systems and household appliances.

D. Infrared Thermal Sensors

Infrared thermal sensors allow for non-contact temperature measurement, making them ideal for various applications.

Characteristics and Applications: These sensors can measure the temperature of an object without direct contact, making them suitable for moving objects or hazardous environments.

Popular Models:

FLIR Lepton: A compact thermal imaging sensor used in various applications, including drones, smartphones, and industrial monitoring.

Melexis MLX90640: This infrared sensor provides high-resolution thermal images and is used in applications such as automotive and medical devices.

V. Applications of Thermal Resistors

Thermal resistors play a vital role in numerous industries:

A. Industrial Applications

In industrial settings, thermal resistors are used for process control, monitoring equipment temperatures, and ensuring safety in machinery.

B. Consumer Electronics

Thermal resistors are integral to consumer electronics, helping to manage heat in devices like smartphones, laptops, and home appliances.

C. Automotive Industry

In the automotive sector, thermal resistors are used for engine temperature monitoring, climate control systems, and battery management in electric vehicles.

D. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on thermal resistors for accurate temperature control, ensuring comfort and energy efficiency.

E. Medical Devices

In medical applications, thermal resistors are used in devices such as thermometers, incubators, and patient monitoring systems, where precise temperature measurement is critical.

VI. Factors to Consider When Choosing a Thermal Resistor

When selecting a thermal resistor for a specific application, several factors should be considered:

A. Accuracy and Precision

The required accuracy and precision of temperature measurements will dictate the choice of thermal resistor. RTDs are generally more accurate than thermistors.

B. Temperature Range

Different thermal resistors operate effectively within specific temperature ranges. It is essential to choose a model that suits the application's temperature requirements.

C. Response Time

The response time of a thermal resistor is crucial in applications where rapid temperature changes occur. Thermistors typically offer faster response times than RTDs.

D. Environmental Conditions

Consideration of environmental factors such as humidity, pressure, and potential exposure to chemicals is essential when selecting a thermal resistor.

E. Cost Considerations

Budget constraints may influence the choice of thermal resistor. While high-precision sensors may be more expensive, they can provide significant long-term benefits in terms of accuracy and reliability.

VII. Future Trends in Thermal Resistor Technology

A. Advances in Materials and Manufacturing

Ongoing research in materials science is leading to the development of new thermal resistors with improved performance characteristics, such as higher sensitivity and wider temperature ranges.

B. Integration with IoT and Smart Technologies

The integration of thermal resistors with IoT devices is becoming increasingly common, allowing for real-time temperature monitoring and control in smart homes and industrial applications.

C. Miniaturization and Enhanced Performance

As technology advances, there is a trend toward miniaturization of thermal resistors, enabling their use in compact devices without compromising performance.

VIII. Conclusion

Thermal resistors are essential components in a wide range of applications, from industrial processes to consumer electronics. Understanding the different types and popular models of thermal resistors can help engineers and designers make informed decisions for their specific needs. As technology continues to evolve, the future of thermal resistor technology looks promising, with advancements in materials, integration with smart technologies, and enhanced performance on the horizon.

IX. References

A comprehensive list of academic papers, articles, and resources for further reading on thermal resistors and their applications can be provided upon request.

Popular Models of Thermal Resistors

I. Introduction

Thermal resistors, also known as temperature sensors, are crucial components in various electronic and industrial applications. They measure temperature by correlating the resistance of a material to its temperature. Understanding thermal resistors is essential for engineers and designers who need to monitor and control temperature in systems ranging from consumer electronics to industrial machinery. This article will explore the different types of thermal resistors, popular models, their applications, and future trends in thermal resistor technology.

II. Understanding Thermal Resistance

A. Explanation of Thermal Resistance and Its Significance

Thermal resistance is a measure of a material's ability to resist the flow of heat. It is analogous to electrical resistance in circuits, where a higher resistance means less current flow. In thermal systems, a higher thermal resistance indicates that the material is less effective at conducting heat. This property is significant in applications where temperature control is critical, such as in HVAC systems, electronic devices, and automotive applications.

B. Factors Affecting Thermal Resistance

Several factors influence thermal resistance, including:

1. **Material Properties**: Different materials have varying thermal conductivities. Metals like copper and aluminum have low thermal resistance, while insulators like rubber and glass have high thermal resistance.

2. **Geometry and Dimensions**: The shape and size of the material also affect thermal resistance. Thicker materials generally have higher thermal resistance, while larger surface areas can enhance heat transfer.

3. **Environmental Conditions**: Temperature, pressure, and humidity can alter the thermal resistance of materials, impacting their performance in real-world applications.

III. Types of Thermal Resistors

A. Overview of Different Types of Thermal Resistors

Thermal resistors come in various types, each suited for specific applications:

1. **Thermistors**: These are temperature-sensitive resistors that exhibit a significant change in resistance with temperature variations. They are widely used in temperature sensing and control applications.

2. **RTDs (Resistance Temperature Detectors)**: RTDs are highly accurate temperature sensors that use the principle of electrical resistance change with temperature. They are commonly used in industrial applications.

3. **Bimetallic Temperature Sensors**: These sensors consist of two different metals bonded together, which expand at different rates when heated. They are often used in thermostats and temperature switches.

4. **Infrared Thermal Sensors**: These sensors detect infrared radiation emitted by objects, allowing for non-contact temperature measurement. They are used in various applications, including medical devices and industrial monitoring.

IV. Popular Models of Thermal Resistors

A. Thermistors

1. NTC (Negative Temperature Coefficient) Thermistors

NTC thermistors decrease in resistance as temperature increases. They are widely used in temperature measurement and control applications due to their high sensitivity.

Characteristics and Applications: NTC thermistors are known for their fast response times and high accuracy. They are commonly used in temperature monitoring in HVAC systems, automotive applications, and consumer electronics.

Popular Models:

EPCOS B57891: This NTC thermistor is known for its high sensitivity and stability, making it suitable for various applications, including temperature measurement in appliances.

Vishay NTCLE100E3: This model offers excellent linearity and is widely used in medical devices and industrial applications.

2. PTC (Positive Temperature Coefficient) Thermistors

PTC thermistors increase in resistance as temperature rises. They are often used for overcurrent protection and self-regulating heating applications.

Characteristics and Applications: PTC thermistors are known for their ability to limit current flow in overcurrent situations. They are commonly used in power supplies, motor protection, and heating elements.

Popular Models:

EPCOS B57231: This PTC thermistor is designed for overcurrent protection and is widely used in consumer electronics.

Vishay PTC: This model is known for its reliability and is used in various applications, including automotive and industrial systems.

B. Resistance Temperature Detectors (RTDs)

RTDs are known for their accuracy and stability over a wide temperature range.

Characteristics and Applications: RTDs provide precise temperature measurements and are commonly used in industrial processes, HVAC systems, and laboratory settings.

Popular Models:

PT100: This is one of the most common RTD types, with a resistance of 100 ohms at 0°C. It is widely used in various applications due to its accuracy and reliability.

PT1000: Similar to the PT100, this RTD has a resistance of 1000 ohms at 0°C, offering higher sensitivity and is often used in applications requiring precise temperature control.

C. Bimetallic Temperature Sensors

Bimetallic temperature sensors are simple yet effective devices that use the expansion of two different metals to measure temperature.

Characteristics and Applications: These sensors are robust and can operate in harsh environments. They are commonly used in thermostats, temperature switches, and industrial applications.

Popular Models:

Honeywell Bimetallic Thermostats: Known for their reliability and durability, these thermostats are widely used in HVAC systems and household appliances.

D. Infrared Thermal Sensors

Infrared thermal sensors allow for non-contact temperature measurement, making them ideal for various applications.

Characteristics and Applications: These sensors can measure the temperature of an object without direct contact, making them suitable for moving objects or hazardous environments.

Popular Models:

FLIR Lepton: A compact thermal imaging sensor used in various applications, including drones, smartphones, and industrial monitoring.

Melexis MLX90640: This infrared sensor provides high-resolution thermal images and is used in applications such as automotive and medical devices.

V. Applications of Thermal Resistors

Thermal resistors play a vital role in numerous industries:

A. Industrial Applications

In industrial settings, thermal resistors are used for process control, monitoring equipment temperatures, and ensuring safety in machinery.

B. Consumer Electronics

Thermal resistors are integral to consumer electronics, helping to manage heat in devices like smartphones, laptops, and home appliances.

C. Automotive Industry

In the automotive sector, thermal resistors are used for engine temperature monitoring, climate control systems, and battery management in electric vehicles.

D. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely on thermal resistors for accurate temperature control, ensuring comfort and energy efficiency.

E. Medical Devices

In medical applications, thermal resistors are used in devices such as thermometers, incubators, and patient monitoring systems, where precise temperature measurement is critical.

VI. Factors to Consider When Choosing a Thermal Resistor

When selecting a thermal resistor for a specific application, several factors should be considered:

A. Accuracy and Precision

The required accuracy and precision of temperature measurements will dictate the choice of thermal resistor. RTDs are generally more accurate than thermistors.

B. Temperature Range

Different thermal resistors operate effectively within specific temperature ranges. It is essential to choose a model that suits the application's temperature requirements.

C. Response Time

The response time of a thermal resistor is crucial in applications where rapid temperature changes occur. Thermistors typically offer faster response times than RTDs.

D. Environmental Conditions

Consideration of environmental factors such as humidity, pressure, and potential exposure to chemicals is essential when selecting a thermal resistor.

E. Cost Considerations

Budget constraints may influence the choice of thermal resistor. While high-precision sensors may be more expensive, they can provide significant long-term benefits in terms of accuracy and reliability.

VII. Future Trends in Thermal Resistor Technology

A. Advances in Materials and Manufacturing

Ongoing research in materials science is leading to the development of new thermal resistors with improved performance characteristics, such as higher sensitivity and wider temperature ranges.

B. Integration with IoT and Smart Technologies

The integration of thermal resistors with IoT devices is becoming increasingly common, allowing for real-time temperature monitoring and control in smart homes and industrial applications.

C. Miniaturization and Enhanced Performance

As technology advances, there is a trend toward miniaturization of thermal resistors, enabling their use in compact devices without compromising performance.

VIII. Conclusion

Thermal resistors are essential components in a wide range of applications, from industrial processes to consumer electronics. Understanding the different types and popular models of thermal resistors can help engineers and designers make informed decisions for their specific needs. As technology continues to evolve, the future of thermal resistor technology looks promising, with advancements in materials, integration with smart technologies, and enhanced performance on the horizon.

IX. References

A comprehensive list of academic papers, articles, and resources for further reading on thermal resistors and their applications can be provided upon request.