What are the Popular Capacitor Housing Models?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that can release energy when needed. They play a crucial role in various applications, from power supply smoothing to signal coupling and decoupling. The performance and reliability of capacitors are significantly influenced by their housing, which protects the internal components and ensures optimal operation. This article aims to explore popular capacitor housing models, shedding light on their characteristics, applications, and the factors influencing their selection.

II. Understanding Capacitor Housing

A. Definition and Function of Capacitor Housing

Capacitor housing refers to the outer casing that encases the internal components of a capacitor. Its primary function is to provide mechanical protection, electrical insulation, and thermal management. The housing must withstand environmental stresses while ensuring that the capacitor operates efficiently and safely.

B. Materials Used in Capacitor Housings

The choice of material for capacitor housings is critical, as it affects the capacitor's performance and durability. Common materials include:

1. **Plastic**: Lightweight and cost-effective, plastic housings are often used in consumer electronics. They provide good insulation and are resistant to moisture.

2. **Metal**: Metal housings, such as aluminum or steel, offer superior mechanical protection and heat dissipation. They are commonly used in high-performance applications where durability is essential.

3. **Ceramic**: Ceramic housings are typically used in high-frequency applications due to their excellent dielectric properties. They are also resistant to high temperatures and environmental factors.

C. Importance of Housing in Thermal Management, Electrical Insulation, and Mechanical Protection

The housing of a capacitor plays a vital role in thermal management by dissipating heat generated during operation. Effective electrical insulation prevents short circuits and ensures safe operation. Additionally, mechanical protection safeguards the capacitor from physical damage, ensuring longevity and reliability.

III. Types of Capacitor Housings

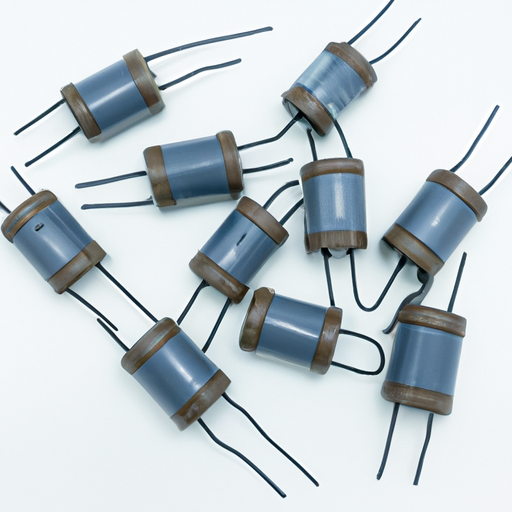

A. Through-Hole Capacitors

Through-hole capacitors are designed for insertion into printed circuit boards (PCBs) through pre-drilled holes. They are widely used in various applications, including power supplies and audio equipment. Popular models include:

Electrolytic Capacitors: Known for their high capacitance values, electrolytic capacitors are commonly used in power supply circuits.

Tantalum Capacitors: These capacitors offer high capacitance in a small package and are used in applications requiring reliability and stability.

B. Surface-Mount Capacitors

Surface-mount capacitors are designed for mounting directly onto the surface of PCBs, allowing for more compact designs. They are prevalent in modern electronics, including smartphones and laptops. Popular models include:

Multilayer Ceramic Capacitors (MLCC): These capacitors are known for their small size and high capacitance, making them ideal for high-frequency applications.

Polymer Capacitors: Offering low equivalent series resistance (ESR) and high ripple current capabilities, polymer capacitors are used in power management applications.

C. Film Capacitors

Film capacitors use a thin plastic film as the dielectric material. They are known for their stability and reliability, making them suitable for various applications, including audio and power electronics. Popular models include:

Polyester Capacitors: These capacitors are cost-effective and widely used in general-purpose applications.

Polypropylene Capacitors: Known for their low loss and high voltage ratings, polypropylene capacitors are used in high-frequency applications.

D. Ceramic Capacitors

Ceramic capacitors are widely used due to their small size and excellent performance characteristics. They are available in various dielectric types, each suited for different applications. Popular models include:

C0G Capacitors: These capacitors offer excellent stability and low loss, making them ideal for precision applications.

X7R Capacitors: Known for their high capacitance values and temperature stability, X7R capacitors are commonly used in decoupling applications.

IV. Popular Capacitor Housing Models

A. Aluminum Electrolytic Capacitors

Aluminum electrolytic capacitors are characterized by their high capacitance and voltage ratings. They are commonly used in power supply circuits, audio equipment, and motor drives. Leading manufacturers include Nichicon, Panasonic, and Rubycon, offering models such as the Nichicon UHE series and Panasonic EEU-FR series.

B. Tantalum Capacitors

Tantalum capacitors are known for their reliability and stability, making them suitable for applications in telecommunications, automotive, and medical devices. Leading manufacturers include KEMET and AVX, with popular models like the KEMET T491 series and AVX TPS series.

C. Multilayer Ceramic Capacitors (MLCC)

MLCCs are widely used in modern electronics due to their small size and high capacitance. They are commonly found in smartphones, tablets, and other compact devices. Leading manufacturers include Murata, TDK, and Yageo, with popular models such as the Murata GRM series and TDK C3216 series.

D. Film Capacitors

Film capacitors are known for their stability and reliability, making them suitable for various applications, including audio and power electronics. Leading manufacturers include WIMA and Vishay, with popular models like the WIMA MKS series and Vishay BFC series.

E. Polymer Capacitors

Polymer capacitors are gaining popularity due to their low ESR and high ripple current capabilities. They are commonly used in power management applications in laptops and smartphones. Leading manufacturers include Panasonic and Nichicon, with popular models like the Panasonic EEU-FR series and Nichicon PL series.

V. Factors Influencing the Choice of Capacitor Housing

When selecting a capacitor housing, several factors must be considered:

A. Application Requirements (Voltage, Capacitance, Size)

The specific requirements of the application, such as voltage rating, capacitance value, and physical size, play a crucial role in determining the appropriate capacitor housing.

B. Environmental Considerations (Temperature, Humidity)

Environmental factors, including temperature and humidity, can significantly impact capacitor performance. Choosing a housing material that can withstand these conditions is essential for ensuring reliability.

C. Cost and Availability

Cost considerations and the availability of specific capacitor models can influence the choice of housing. Manufacturers often provide a range of options to suit different budgets and supply chain needs.

D. Reliability and Lifespan

The reliability and expected lifespan of the capacitor are critical factors, especially in applications where failure can have severe consequences. Selecting a housing that offers durability and long-term performance is essential.

VI. Future Trends in Capacitor Housing

A. Innovations in Materials and Design

The capacitor industry is witnessing innovations in materials and design, with manufacturers exploring new dielectric materials and housing designs to enhance performance and reduce size.

B. Impact of Miniaturization on Housing Models

As electronic devices continue to shrink in size, the demand for smaller and more efficient capacitor housings is increasing. This trend is driving the development of advanced packaging techniques and materials.

C. Sustainability and Eco-Friendly Materials

With growing environmental concerns, manufacturers are increasingly focusing on sustainability. The use of eco-friendly materials and recyclable designs is becoming a priority in capacitor housing development.

VII. Conclusion

In conclusion, capacitor housing plays a vital role in the performance and reliability of capacitors in electronic circuits. Understanding the various types of capacitor housings, their characteristics, and applications is essential for selecting the right component for specific needs. As technology advances, the capacitor industry will continue to evolve, with innovations in materials, design, and sustainability shaping the future of capacitor housing.

VIII. References

1. "Capacitor Basics: Understanding Capacitors and Their Applications." Electronics Tutorials.

2. "The Role of Capacitor Housing in Performance and Reliability." IEEE Transactions on Components, Packaging and Manufacturing Technology.

3. Manufacturer websites: Nichicon, Panasonic, KEMET, Murata, WIMA, and AVX for product specifications and details.

This comprehensive overview of popular capacitor housing models provides valuable insights for engineers, designers, and enthusiasts looking to understand the critical role of capacitors in modern electronics.