What are the Advantages of Standard Capacitor Products?

I. Introduction

Capacitors are fundamental components in electronic circuits, serving various roles such as energy storage, filtering, and signal coupling. A standard capacitor is a pre-manufactured component that adheres to specific values and specifications, making it widely available and easily integrated into designs. This article aims to explore the advantages of standard capacitor products, highlighting their significance in modern electronics.

II. Overview of Capacitor Types

Capacitors come in various types, each with unique characteristics suited for different applications. The most common types include:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors are polarized and typically used in power supply circuits.

2. **Ceramic Capacitors**: These non-polarized capacitors are valued for their stability and reliability, making them ideal for high-frequency applications.

3. **Film Capacitors**: Offering excellent performance in terms of stability and low losses, film capacitors are often used in audio and power applications.

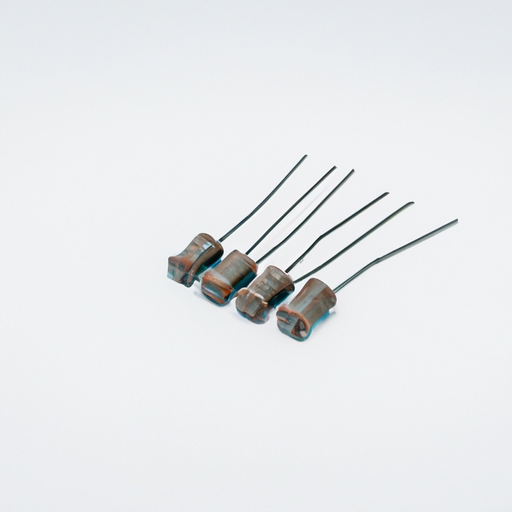

4. **Tantalum Capacitors**: Known for their compact size and high capacitance, tantalum capacitors are used in applications where space is a premium.

Standard capacitors differ from custom capacitors, which are tailored to specific requirements. While custom capacitors can meet unique needs, standard capacitors offer numerous advantages that make them a preferred choice in many scenarios.

III. Advantages of Standard Capacitor Products

A. Cost-Effectiveness

One of the primary advantages of standard capacitor products is their cost-effectiveness. Manufacturers produce standard capacitors in large quantities, leading to economies of scale. This mass production results in lower unit costs compared to custom solutions, making standard capacitors an attractive option for budget-conscious projects.

B. Availability and Accessibility

Standard capacitors are readily available from multiple suppliers, ensuring that engineers and designers can easily source the components they need. With a wide range of standard values and specifications, finding the right capacitor for a specific application is often a straightforward process. This accessibility reduces lead times and helps maintain project schedules.

C. Consistency and Reliability

Standard capacitors benefit from established manufacturing processes that ensure consistency and reliability. Manufacturers adhere to strict quality assurance and testing standards, resulting in components that perform predictably across various applications. This reliability is crucial in electronic designs, where component failure can lead to significant issues.

D. Simplified Design Process

The use of standard capacitors simplifies the design process for engineers. Standardization in circuit design allows for easier integration of components, reducing complexity in component selection. Designers can focus on other critical aspects of their projects, knowing that standard capacitors will meet their performance requirements.

E. Compatibility and Interchangeability

Standard capacitors are designed with standardized dimensions and ratings, making them compatible with a wide range of applications. This compatibility allows for ease of replacement and upgrades, as engineers can swap out components without worrying about fit or performance discrepancies. This interchangeability is particularly beneficial in maintenance and repair scenarios.

F. Performance and Efficiency

Standard capacitors are optimized for common applications, ensuring that they deliver reliable performance. Manufacturers conduct extensive testing to establish performance metrics, allowing designers to select components with confidence. This proven performance is essential in applications where efficiency and reliability are paramount.

IV. Applications of Standard Capacitor Products

Standard capacitors find applications across various industries, demonstrating their versatility and importance.

A. Consumer Electronics

In consumer electronics, standard capacitors are ubiquitous. They are used in smartphones, tablets, and home appliances, where they play critical roles in power management, signal processing, and noise filtering. Their reliability and cost-effectiveness make them ideal for mass-produced devices.

B. Industrial Applications

In industrial settings, standard capacitors are essential for automation and control systems. They are used in power supply circuits to smooth out voltage fluctuations and ensure stable operation. Their robustness and reliability are crucial in environments where equipment must operate continuously.

C. Automotive Industry

The automotive industry increasingly relies on standard capacitors, especially with the rise of electric vehicles and advanced infotainment systems. Capacitors are used in power management systems, energy storage, and signal processing, contributing to the overall performance and efficiency of modern vehicles.

D. Telecommunications

In telecommunications, standard capacitors are vital for signal processing and network equipment. They help filter signals, stabilize voltages, and ensure reliable communication. The demand for high-performance capacitors in this sector underscores their importance in maintaining connectivity.

V. Challenges and Considerations

A. Limitations of Standard Capacitors

While standard capacitors offer numerous advantages, they are not suitable for all applications. In specialized scenarios, such as high-frequency or high-voltage applications, custom capacitors may be necessary to meet specific performance requirements. Understanding these limitations is crucial for engineers when selecting components.

B. Importance of Proper Selection

Proper selection of standard capacitors is essential to ensure optimal performance. Engineers must understand the application requirements and evaluate specifications and tolerances carefully. This diligence helps avoid potential issues related to component failure or suboptimal performance.

VI. Future Trends in Capacitor Technology

As technology continues to evolve, so does the landscape of capacitor products. Innovations in standard capacitor design are emerging, driven by the need for higher performance and efficiency. Additionally, the impact of emerging technologies, such as electric vehicles and renewable energy systems, is shaping the future of capacitor applications.

Sustainability and environmental considerations are also becoming increasingly important. Manufacturers are exploring eco-friendly materials and production processes to reduce the environmental impact of capacitor production. This trend aligns with the broader movement toward sustainability in the electronics industry.

VII. Conclusion

In summary, standard capacitor products offer numerous advantages that make them a preferred choice in various applications. Their cost-effectiveness, availability, consistency, and reliability contribute to their widespread use in modern electronics. As technology continues to advance, standard capacitors will play a crucial role in supporting innovation and efficiency.

Engineers and designers are encouraged to consider standard options in their projects, leveraging the benefits these components provide. By understanding the advantages of standard capacitors, professionals can make informed decisions that enhance the performance and reliability of their electronic designs.

VIII. References

1. "Capacitor Basics: Understanding Capacitors and Their Applications." Electronics Tutorials.

2. "The Role of Capacitors in Electronic Circuits." IEEE Spectrum.

3. Manufacturer websites and product catalogs for further reading on standard capacitor specifications and applications.

This blog post provides a comprehensive overview of the advantages of standard capacitor products, emphasizing their significance in various industries and applications. By understanding these benefits, engineers can make informed choices that enhance their designs and projects.